Uses of Titanium Dioxide Powder in Various Applications

Introducing our premium titanium dioxide for masterbatches, a versatile, high-quality additive specifically designed to improve the opacity and whiteness of plastic products. Our products offer exceptional properties, including low oil absorption, excellent compatibility with plastic resins and rapid, complete dispersion.

Our titanium dioxide for masterbatches is ideal for a variety of applications, including polypropylene masterbatch production. With its excellent quality and performance, it is the perfect solution for achieving the desired color and opacity of plastic products.

Our products are available in fine powder form, making them easy to incorporate into masterbatch formulations. Its high purity and consistent particle size ensure even dispersion and excellent color consistency in the final plastic product.

One of the key advantages of our titanium dioxide for masterbatches is its low oil absorption, which means it can be used in formulations without affecting the overall performance of the plastic resin. This saves costs and increases the efficiency of the production process.

Additionally, our titanium dioxide for masterbatches has excellent compatibility with a wide range of plastic resins, ensuring it can be seamlessly incorporated into a variety of formulations without compromising performance or quality. Its compatibility with different resins makes it a versatile choice for manufacturers looking to achieve consistent color and opacity in plastic products.

Additionally, our products are known for their fast and complete dispersion, allowing for easy and effective mixing with other masterbatch ingredients. This ensures that the titanium dioxide is evenly distributed throughout the plastic matrix, resulting in a uniform color and opacity in the final product.

Whether you are producing polypropylene masterbatches or other plastic products, our titanium dioxide is the perfect choice to achieve the desired whiteness and opacity. Its exceptional performance, versatility and ease of use make it a valuable addition to any masterbatch formulation.

In summary, our titanium dioxide for masterbatch is a high-quality additive with excellent performance, excellent compatibility and ease of use. With its low oil absorption, fine powder form and rapid dispersion, it is ideal for achieving consistent color and opacity in plastic products. Choose our titanium dioxide for masterbatches to improve the quality and performance of your plastic formulations.

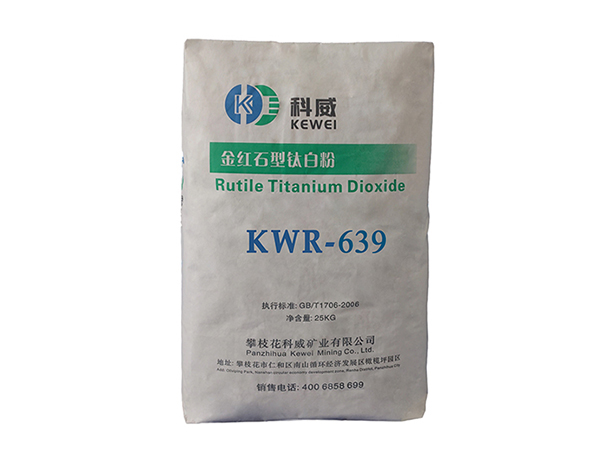

Package

Basic Parameter

| Chemical name | Titanium Dioxide (TiO2) |

| CAS NO. | 13463-67-7 |

| EINECS NO. | 236-675-5 |

| ISO591-1:2000 | R2 |

| ASTM D476-84 | III, IV |

Technical lndicator

| TiO2, % |

98.0

|

|

Volatiles at 105℃, %

|

0.4

|

|

Inorganic coating

|

Alumina

|

|

Organic

|

has

|

|

matter* Bulk density (tapped)

|

1.1g/cm3

|

|

absorption Specific gravity

|

cm3 R1

|

|

Oil Absorption,g/100g

|

15

|

|

Color Index Number

|

Pigment 6

|