Titanium dioxide, commonly known as TiO2, is a versatile pigment used in various industries. It is known for its excellent light scattering properties, high refractive index and UV protection. There are different types of TiO2, each with unique properties and applications. In this blog, we will explore the various types of titanium dioxide and their uses in different industries.

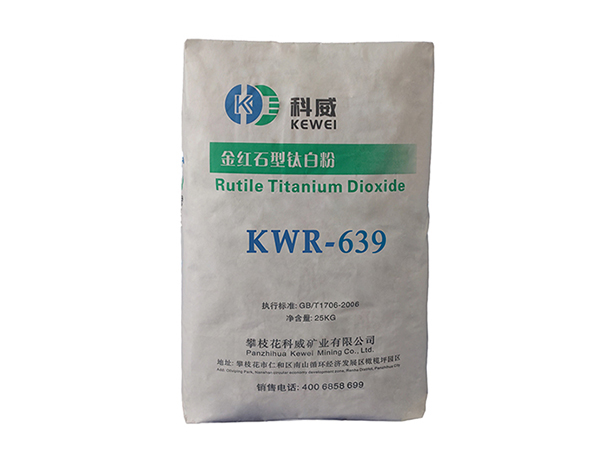

1. Rutile TiO2:

Rutile titanium dioxide is one of the most commonly used forms of titanium dioxide. It is known for its high refractive index, which makes it ideal for applications requiring high opacity and brightness. Rutile titanium dioxide is widely used in the production of paints, coatings, plastics and paper, and its excellent light scattering properties can improve the whiteness and brightness of the final product.

2. Anatase titanium dioxide:

Anatase titanium dioxide is another important form of titanium dioxide. It is characterized by high surface area and photocatalytic properties. Anatase TiO2 is commonly used in the production of photocatalytic coatings, self-cleaning surfaces and environmental remediation applications. Its ability to catalyze the decomposition of organic compounds under UV light makes it a valuable material for air and water purification systems.

3. Nano titanium dioxide:

Nano-TiO2, also called nanoscale titanium dioxide, is a type of TiO2 with a particle size in the nanometer range. This ultrafine form of TiO2 has enhanced photocatalytic activity, high surface area and improved light scattering properties. Nanoscale titanium dioxide has a wide range of applications, including sunscreen formulations, cosmetics, environmentally friendly coatings and antibacterial materials. Its small particle size provides better coverage and protection in sunscreens and UV-blocking coatings.

4. Coated titanium dioxide:

Coating TiO2 refers to coating titanium dioxide particles with inorganic or organic materials to improve their dispersion, stability and compatibility with different matrices. Coated TiO2 is commonly used in the production of high-performance coatings, inks and plastics, where uniform dispersion of TiO2 particles is critical to achieving desired properties such as durability, weather resistance and color stability.

In summary, different types of TiO2 have a wide range of properties and applications across industries. From improving the whiteness of paints and coatings to providing UV protection in sunscreens to improving air and water quality through photocatalysis, titanium dioxide plays a vital role in numerous products and technologies. As nanotechnology research and development continues to advance, we can expect to see further innovations and applications for titanium dioxide in the future.

Post time: Jun-15-2024