In the field of plastics, the use of additives and fillers is crucial to improve the properties and performance of the final product. Titanium dioxide is an additive that is getting a lot of attention. When added to polypropylene masterbatch, titanium dioxide can provide a range of benefits, from improved UV resistance to enhanced aesthetic appeal.

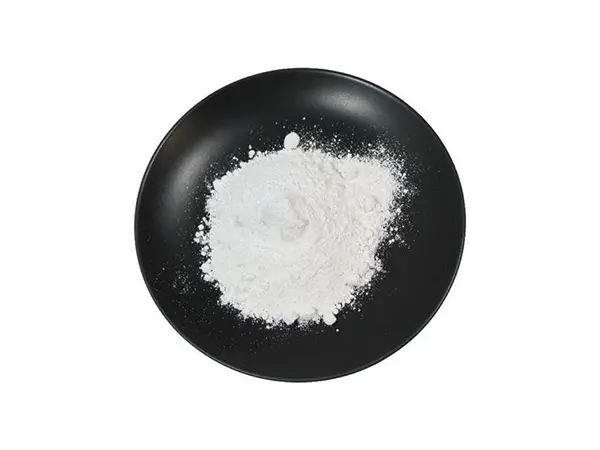

Titanium dioxide is a naturally occurring titanium oxide known for its ability to impart whiteness, brightness, and opacity to a variety of materials. In plastics, it is often used as a pigment to achieve vibrant colors and provide protection against the harmful effects of UV radiation. For polypropylene masterbatch, the addition of titanium dioxide can have a profound impact on the overall quality of the final product.

One of the main advantages of adding titanium dioxide to polypropylene masterbatch is its ability to enhance UV resistance. Polypropylene is a popular thermoplastic polymer known for its versatility and is used in a wide range of applications from packaging to automotive parts. However, prolonged exposure to sunlight can cause the material to degrade, resulting in discoloration and reduced mechanical properties. By incorporating titanium dioxide into the masterbatch, the resulting polypropylene product can better resist the damaging effects of UV radiation, extending its life and maintaining its visual appeal.

In addition, the addition of titanium dioxide can significantly improve the aesthetic properties of polypropylene masterbatch. The pigment acts as a whitening agent, increasing the whiteness and opacity of the material. This is particularly advantageous in applications where a pristine, uniform appearance is required, such as in the production of consumer goods, household goods and medical devices. The enhanced visual appeal through the use of titanium dioxide can increase the perceived value of the final products, making them more attractive to consumers and end users.

In addition to visual and protective benefits, titanium dioxide can improve the overall performance of polypropylene masterbatches. By effectively scattering and reflecting light, pigments can help reduce heat build-up within the material, thereby helping to improve thermal stability. This is particularly important in applications where temperature resistance is a key factor, such as the manufacturing of automotive parts and electronic equipment.

It is important to note that the successful incorporation of titanium dioxide into polypropylene masterbatch relies on the use of a high-quality masterbatch formulation. The dispersion of pigments in the polypropylene matrix is critical to ensure uniform coloration and optimal performance. Therefore, manufacturers must carefully select a masterbatch supplier with the expertise and technology to achieve consistent and reliable titanium dioxide dispersion.

In summary, adding titanium dioxide to polypropylene masterbatch offers many advantages, from enhanced UV resistance to improved aesthetics and performance. As the demand for high-quality, beautiful and durable plastic products continues to rise, the role of titanium dioxide in polypropylene masterbatches will become increasingly important. By harnessing the potential of this versatile pigment, manufacturers can improve the quality and marketability of their polypropylene products to meet the changing needs of various industries and consumers.

Post time: May-06-2024